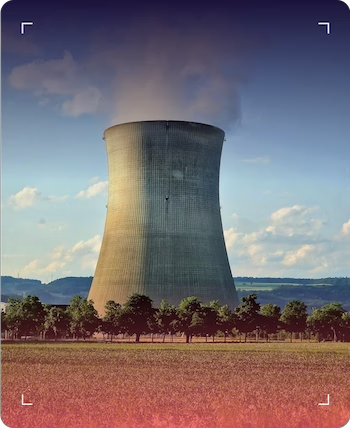

The ABMI Group has been active in the energy sector for over 20 years. We operate in the fields of civil nuclear power, renewable energy, and environmental facilities.

Production site design, calculations, specialised studies, works management, quality control

Project management, project ownership, project management assistance, subcontractor coordination

Power electrical networks, Low-power electrical networks, Control-Command and automation systems

Thermal studies, Thermodynamic studies, Obsolescence studies, Modernisation studies, 3D analyses

Our multi-disciplinary design offices design, develop, industrialise and test the specialised tools and machinery that our customers need for their business. These machines, often one-offs, are developed to order.

Drafting of FACRs (Regulatory Framework Analysis Sheets) and NACRs (Regulatory Framework Analysis Notes), Impact assessments of AIPs/EIPs/EISs, Support for drafting RGEs, Consideration of operational safety in design

Life cycle analyses, facility lifespan analyses, drafting of maintenance schedules, spare parts consumption forecasts, drafting of general test programmes (GTPs) and monitoring of commissioning tests

Ensure reliable deliveries, reduce non-quality costs, and strengthen competitiveness by improving the supply chain, production methods, and process control.

Studies enabling the remanufacturing and improvement of mechatronic components and assemblies without the specifications or traceability of your original supplier.

Civil engineering, project management, water treatment, dimensioning, urban planning, project management, catenary studies, HVAC and fluids, mechanics, passenger information, transport systems, quality… Our employees work on all building and transport infrastructure: metro, train, tramway and bus.

Real-time 3D applications: From customising standard solutions to tailor-made developments. Advice for safe and sensible adoption: From identifying uses to choosing technologies. Design of innovative, tailor-made tools.

Architecture and modelling of industrial and specialised vehicles. Support from design and product development to industrialisation.

Specialising since 2007 in the design and development of native iOS and Android mobile applications, Openium has a team of 34 employees. The agency has all the internal resources necessary to successfully design the mobile projects entrusted to it.

Since 2007, Rtone has been developing smart, connected products. With its multidisciplinary team, Rtone supports you throughout your project, from defining use cases to leveraging data.

ABMI ensured a significant, rapid and high-quality ramp-up in staff numbers, structured around an organisation that guarantees the quality of deliverables and service levels. Service continuity was maintained despite operational difficulties during the COVID crisis.

We initially called on Rtone to carry out a technical audit of the product in autumn 2020. We were very satisfied with the quality of their analysis, and when it came time to choose a partner to help us industrialise and bring the system into production, we decided to place our trust in them and continue working with them. Their technical expertise and ability to deliver were real strengths in getting the product to market.

Following pipework modifications at two sites based in Nantes (two boiler lines), IDEX entrusted us with checking the integrity of the supports at the top of the pipework and the integrity of the bases and supports of the motor pump line (lower part of the installation). Following our assessment and verification of the existing supports, 11 of the 14 supports were replaced.

VEOLIA Waste Management wishes to convert a waste sorting facility into a RDF (Refuse Derived Fuel) production centre. VEOLIA has entrusted ABMI with the project management.

During the works, the client wished to exercise options for ABMI to take on additional lots.

ABMI offered design support with 3D plans to help the client integrate its process.